Alice in EASAland – The revised Guide to the Airworthiness Review

Issue 1 30/03/12

Its over three years now since the Blue Peter Guide heralded the arrival of that lovely new EASA airworthiness nonsense that we have all now come to love with a passion deeper than the Mariana Trench so here is a bit of an update on the things you need to know in order to make it easier complete the Airworthiness Review Report. Nothing much has changed on the form, however there are some aspects that need a bit of a reminder and some areas where the information supplied is often not quite what was asked for! As this will not necessarily be the first time the balloon (or airship) has had an Airworthiness Revue (Freudian slip), and as some ARC signatories are either training, have more practise than others or may not have a memory capable of going back three years, here is a bit of help. So, pens and paper at the ready and a mug of tea (or bottle of scotch) to hand.

As we normally combine the Annual/100hour inspection with the ARC issue we have found that the easiest way to fill in this bunch of bananas in is to complete as much of the information on the Inspection Sheet first then simply transpose the information over. However this may not be everybody’s method so we will go through the process bit by bit according to the layout of the Airworthiness Review Report. Where links are handy they will be embodied in the text but all the Links are listed at the end.

We all now realise that you need both the Annual/I00 hour inspection and an ARC for an aircraft to be current. Any suitably qualified and rated inspector under the control of a Subpart F Organisation can carry out the Annual/100hour inspection. Balloon-wise only an ARC signatory under the control of a Subpart G Organisation can carry out an Airworthiness Review and issue an ARC. It therefore follows that it may be the case that a balloon owner may elect to enlist the services of a Subpart G CAMO for the issue of an ARC so an Airworthiness Review could easily be carried out separately to the Annual/100hour inspection. This could certainly be the case where the Inspector is not yet qualified to be an ARC signatory. If this is the case a Survey Report will still need to be completed. Usually the Physical Survey Report doubles as the Inspection Report.

Once completed the Airworthiness Review (along with the Physical Survey Report Form) is the thing that allows the ARC to be issued so fill it in wrong and you can’t issue, or rather you may well be falsely issuing, an ARC.

The Airworthiness Review Report.

A simple enough thing to say but this must be completed accurately and correctly. It will form the main data for the CAMO looking after the balloon and will be one area you will most certainly be audited against when your time comes. The CAMO looking after the balloon will note inaccuracies and inform you accordingly so please get it right. If you have any problems call a BBAC senior inspector, ask the CAMO looking after the balloon or the Manufacturer for clarification. Do not guess or assume!

So, in the traditional way, glass full, we will start at the top and work down point by point. So on the top right we have a nice little box to fill in… Contract/Workpack Ref

This will be the same reference number entered at the top of the IR10/11 Inspection Sheet. It should read in the form of the Registration without the G- followed by the date expressed as ddmmyyyy where d=day, m=month and y=year. So if the registration is G-ODAY its 3rd April 2012 it will should read as ‘ODAY03042012’. It needs to go at the top of each page.

PART 1. AIRCRAFT DETAILS

Registration needs to be correct (It should match at least the first bit of the Contract/Workpack number).

Type is exactly that. Manufacturer followed by the details as they are in G-INFO. Do not assume that the details in the front of the logbook are necessarily accurate. A Thunder 56 Bolt (as it appears in the logbook) is actually a Thunder AX6-56 Bolt. A Lindstrand 105A is really a Lindstrand LBL105A. The CAA know best and are never wrong so check there first.

http://www.caa.co.uk/application.aspx?catid=60&pagetype=65&appid=1

Serial number is the serial number of the balloon and should match the one in G-INFO against the registration.

EQUIPMENT

Now when you did the first Review back in 2009 you would have ensured that the details in the front of the logbook were correct and the type, serial number and weights were correctly entered into the appropriate bit of the balloon logbook. Experience has shown that this may not always be the case though so don’t be afraid of checking. The appropriate manufacturers Flight Manual should contain all the information you need and they are available on line if the owner has taken his copy home!

It is important that the Equipment Type is described as accurately as possible. If the balloon is in the CAMO then this is what identifies it to the CTO who can then check it against any ADs or SBs that are issued. For example Cameron burners with adjustable frames have a different part number to those with fixed frames. If there was a problem with, say the knobs, on an adjustable CBL frame, it is important that it is identified as such. So if you have listed a double Shadow burner in an adjustable frame as a CB2222 (which, sad man, should be a CB2215) then it could be missed.

Serial numbers can easily be mis-read or copied incorrectly and must be recorded as they are. Don’t leave the ‘J’ off the Worthington cylinder if it has one nor add one if it hasn’t. Take care when recording and double-check.

Fuel Cylinders need to be described accurately. With Sky, Lindstrand and T&C using the term V30, for example, it is important that you prefix the Type with the manufacturer or if you can find it use the part number again prefixed by the Manufacturer. So a Thunder and Colt V30 serial number V30 1234 needs to be entered as T&C V30 under Type and V30 1234 under Serial Number. Some T&C and Lindstrand cylinders only have a number forming the serial number so if V30 doesn’t appear as part of the serial number it isn’t in the serial number! A Lindstrand V30 serial number 234 DOES NOT have a serial number V30 234. Cameron and Ultramagic cylinders have a clearly defined Type such as Cameron CB599 or Ultramagic M40. The downside is that a doctor engraves the Serial Numbers so it is often nigh on impossible to read them! A torch held at a jaunty angle helps.

Burner – same rule applies Manufacturer and part number first. For older burners you may have to look in the Supplements to the Flight Manual for a part number if the previous inspector just described it as a CBL Mk4. It is important that this is correct. Beware as again there are subtle differences between apparently similar burners especially early Cameron MkIVs. Lindstrand and Ultramagic usually engrave the Part number on their burners.

Basket/Gondola suggests immediately ‘delete as appropriate’. Gondolas are boats and have no place here! As before prefix the Type with the manufacturer. Now we could be in the area of uncertainty here when it comes to Type, especially with early Cameron and T&C baskets. Check the logbook first for details. If that doesn’t work then you may have a bit of a job on your hands and you may end up calling another inspector, the CTO or the manufacturer. If there is no recorded Serial Number, especially in the case of early Cameron baskets and a lot of the older T&C baskets then use the envelope serial number. Most problems with baskets affect the floor so if you can only describe the basket by measurement then state the type of floor as well (wicker/solid).

Hot-air-airships are noisy all the time and the engine and propeller may have their own logbooks. You’ll require the make, type and serial numbers of them. Usually pretty straightforward. Any problems ground it.

Total hours to Dec previous

Clearly written by someone who is slightly dyspexic! What this means is the total hours upto the end of the previous December! Don’t forget to add tethered hours.

Current Hours

Well pretty obvious but don’t forget to add tethered hours and in the case of a balloon operating in an AOC that the Techlog hours and the Total hours match. There is often a difference which is not acceptable as this will be checked by the CAMO against the Techlog returns. If they don’t match then the hours are incorrect somewhere along the line so the ARC cannot be issued.

Certified MTOM

Easy to get this wrong but jolly easy to get it right. It should be in the Flight Manual but it is amazing that a lot of owners have no idea what it means! Beware the MTOM can be reduced for insurance purposes. There should be an entry in the logbook confirming this. Easiest way to find the MTOM is through G-INFO, which is never wrong! (http://www.caa.co.uk/application.aspx?catid=60&pagetype=65&appid=1).

Downrating the MTOM is not the same as Reducing the MTOM. If an envelope fails the grab test and a lower lift per 1000cu.ft. is applied that is not a ‘reduced MTOM’, the original MTOM still applies.

Airworthiness Review Period

Not quite as simple as it was first time back in swinging ‘09. It is from the date of issue of the last Airworthiness Review. Generally this is the date of Issue of the last ARC not the extension.

If the balloon HAS been in a CAMO for the past three or so years it will be from the date of issue of the last Airworthiness Review NOT the last ARC extension or last annual inspection date. The date you want is therefore the initial date of issue of the ARC.

If it has NOT been in a CAMO it may (providing it hasn’t exceeded 100hours in the last year!) have had an Airworthiness Review at the same time as the annual inspection so the date you are looking for is the date of issue of the last ARC. Bear in mind if the ARC has expired and it hasn’t been used then the Period may be over a year.

If it is a balloon requiring Transition from the old CAA Certificate of Airworthiness to a super-duper EASA gold-plated thing then the Review period will be from the last annual inspection which used to double up with the Airworthiness Review.

Where there is a gap of a year or more when the balloon has neither had an annual inspection or Review, so has been technically non-airworthy, make a note of where and how the balloon has been stored (nice warm garage) and attach it to the Review.

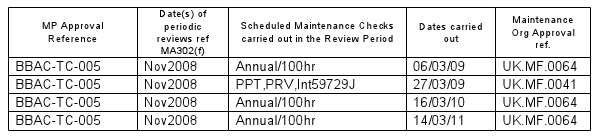

The table that is the Scheduled Maintenance

This is where you record the scheduled Maintenance Checks that have been carried out during the Review Period. what has been done to the balloon during the review period. This is where the Maintenance Programme (MP) specific to the balloon comes in. It is a check to ensure the requirements of the Maintenance Programme have been complied with. So firmly grasping the Maintenance Programme in one hand and the Balloon Logbook in the other you’ll have to get someone else to do the writing!

The Maintenance Programme Approval Reference is the number on the top of the Maintenance Programme. The Maintenance Programme you quote is the one for the specific balloon.

The date of the periodic review is found at the bottom of the current Issue of the Maintenance Programme provided. Beware though as there may have been a review of the Maintenance Programme during the period you are reviewing.

Scheduled Maintenance Checks Generally the first entry will be the annual that was carried out along with the initial ARC issue three years previously. Additional items would be PPTs and PRV replacement.

Maintenance Org Approval› ref is the Subpart F number under which the work was carried out and should be written, or a sticker quoting it placed, alongside the logbook entry. Scheduled Maintenance may not necessarily have been carried out under the BBAC CAMO. If the work has been carried out under another CAMO then their Approval reference must be quoted.

Below is a jolly fine example of how the block should or could look:

PART 2. AIRWORTHINESS REVIEW DETAILS

That’s the fun bit over now onto the really important stuff that proves the balloon will continue to be kept in a safe and proper manner.

2.1 The balloon conforms to the correct amendment of the Flight Manual(s) and the correct supplements are inserted YES/NO

Naturally the balloon conforms to the correct amendment of the Manuals so the answer is YES. Now you need to prove it by quoting the Flight Manual in use. Ensure, when required (applicability can be found in the appropriate TCDS), that the latest Issue and Amendment of the Flight Manual is being used where appropriate. If older equipment is being used you may need a Supplement or two. There are some unlikely ones that are required but seldom listed like Lindstrand’s Supplement 14 or Cameron’s 8.2 when dealing with big ride baskets.. Interesting reading there then! Which actual Flight Manual can be used is listed in the TCDS. Generally balloons pre-2003 can use the original manual. If newer equipment is used in relation to the envelope then it may not be listed in the original manual so you may have to use a later manual. You need to be sure that all the safety information to operate the balloon and its components safely are available.

2.2 All scheduled maintenance required in the listed Maintenance Programme(s) detailed above has been carried out YES/NO

Bit of an obvious one, of course it has so the answer is YES. A NO may be that a cylinder has been removed so it may not have been PPT’d.

2.3 All known defects have been corrected or deferred in accordance with an approved procedure (M.A.403) YES/NO

Yup, all the known defects should have been corrected or listed as deferred so the answer is YES. The procedure quoted, MA.403, can be found in a smashing little book called Continuing Airworthiness Requirements – Part M and basically says M.A.403 AIRCRAFT DEFECTS (a) Any aircraft defect that hazards seriously the flight safety shall be rectified before further flight’ The procedure used by the CAMO reflects this and is in the Company’s Continuing Airworthiness Management Exposition.

2.4 All applicable Airworthiness Directives (ADs) have been incorporated YES/NO

This means that they have been checked and where necessary have been acted on and all the details entered into the logbook. To the logbook first then. In the back of the logbook, are all the AD’s and SB’s applicable to the balloon listed and up to date? Are there logbook entries during the period to support that? If they aren’t then you’ll have to sort them out. Ensure that you do make sure that ALL active ADs (and SBs) relating to the balloon are included and state whether they are applicable or not and give the reason. Those that are ‘closed’ can be omitted providing that they were raised prior to the construction of the balloon. Where older equipment is used bear in mind that the older ADs (and SBs) may apply. Where a different manufacturers’ equipment is used then ADs (and SBs) relating to that equipment must also be checked and referenced. Later logbooks have provision at the back for listing both applicable and non-applicable ADs and SBs. Where none exist then a template should be made up and used.

Documents assessed refers to where the information relating to the ADs was sourced. The easiest place to check for all the old and current ADs (and SBs) is the manufacturers website but you must check the other sources.

Item (i) CAA CAP 747 up to Issue no/Amendment number

To get the magic numbers go to www.caa.co.uk/cap747 which takes you to the front page of this fine document and also gives the current date of issue, Issue number and Amendment number. From here you can also open the main document. Type in the manufacturers name to find the details.

Item (ii) Aircraft State of Design Airworthiness Directives upto..Date

This refers to the Country where the balloon was designed and probably manufactured. Thus an Ultramagic requires a gander at the Spanish DGAC and a Cameron, the CAA and the date of the Review should be quoted.

Item (iii) Equipment State of Design Airworthiness Directives upto..Date

This is the equipment separate to the envelope so if you have a Lindstrand Balloon flying on an Ultramagic bottom end and using Kubicek cylinders you’ll have three NAAs ADs to check and the date of the Review quoted. Lovely!

Item (iv) Published EASA Airworthiness Directives upto Bi-weekly/Date

EASA bi-weeklies are issued bi-weekly (bit of a coincidence) so will often be upto two weeks out of date. Technically, quoting the date is better than the Issue number but if they insist you need to go to http://ad.easa.europa.eu/biweekly.

Item (v) The reference to EASA SINs/SIBs in Item (v) means a trip to the wonderful EASA website. SIN stands for Safety Information Notice and are recommendations, SIB stands for EASA Safety Information Bulletin and are for information only. If you go through www.europa.eu/ws_prod/g/g_about.php it takes you straight to the English bit without having to get phased by the double-decker Airbus and strange language selection list. Once in, type the manufacturers’ name followed by SIN or SIB. The manufacturers are now issuing these darlings as well so best have a squint there as well.

Items (vi) and (vii) (where appropriate) is a bit for hot-air-airships is….a bit for hot air airships! You may well have to search about a fair bit to get the information as a variety of propellers and engines are used from various countries. If you have any problems the easiest solution is to pour a large scotch and contact the gondola manufacturer.

2.5 All the life limited components have been recorded and have not exceeded their approved service life YES/NO

I know, bit daft to answer NO so after checking the answer should be YES. The replacement date of lifed components, or next inspection date due, should be recorded in the logbook, on an Certificate of Release to Service or both. The details of the bits you’ve inspected and any lifed components should have been recorded on the Inspection Sheet.

2.6 All maintenance completed or carried out within this review period has been undertaken by an approved maintenance organisation (not including Limited Pilot Maintenance) YES/NO

Pretty self-explanatory and the answer needs to be YES. Particularly in the case of Ride Balloons ALL Maintenance should have been carried out by Part M Subpart F organisation. In all cases, if any repairs or maintenance has been carried out then the details, along with Workpack or Jobsheet references, should have been entered in the logbook along with a Release to Service and the Reference Number of the Subpart F Maintenance Organisation that carried them out. The Workpack or Jobsheet references along with the Subpart F Approval number should be entered below. This is Maintenance as opposed to Scheduled Maintenance which was listed in Part 1.

2.7 Has any Pilot Maintenance been undertaken in accordance with M.A.803(b) YES/NO

No Pilot Maintenance is approved for Ride Balloons so in this case the answer should be NO. In the case of Privately owned balloons, as long as the requirements of M.A.803 (revisit to that lovely little Part M book required) which defines Pilot-owner authorisation are met then the balloon, if it is in a CAMO will remain in it. What Pilot Maintenance is permitted is determined by the CAMO and can be found in the Maintenance Programme.

2.8 Is the weight and component weighs correctly recorded in the logbook YES/NO

The weights of everything must be recorded in the front pages of the logbook. Sometimes they are in a bit of a state so you may have to make up a new spread sheet. If you do then ensure that all the other out-of-date stuff is crossed out with a single strike-through and you date the new sheet. Component weights can be found in the appropriate Flight Manual. Lindstrand’s Flight Manual is a cracker and does list other manufacturers’ weights. The date last weighed is usually the date of manufacture.

2.9 The balloon conforms to the latest revision of the EASA type/design approval YES/NO

This should be the first question! Muppetry. The answer is going to have to YES otherwise you’ve wasted an hour or two but have at least enjoyed a bottle or two. It must appear on an EASA Type-Certificate Data Sheet. Go to http://easa.europa.eu/certification/type-certificates/balloons.php where you will find the manufacturer along with the latest revision of the TCDS. Open it up and scroll the contents until you find the make and model you are working on. Couple of notes. CameronGB refers to Cameron gas balloons, SSHAB means special shape hot air balloon, Lindstrand has a separate one for all their types and its easy to accidently mistake the Lindstrand Cloudhopper number for the Lindstrand A-type number.

2.10 Aircraft documentation reviewed

States what you reviewed and of course you have, haven’t you? You should have reviewed the:

(i) Certificate of Registration, is it the correct EASA type?

(ii) Certificate of Airworthiness, again is it the correct EASA type?

(iii) Aircraft logbook, is it complete and ALL aspects upto date

(iv) Radio License, No need to worry about the radio bit unless there is an installation like what there is in some airships.

(v) Flight Manual and Supplements, Did they actually bring one?

In the case of airships (if appropriate)

(vi) Engine logbook, regarded by pilots as the noisy oily bit.

(vii) Propeller logbook, The spinnything you don’t get close to.

2.11 (IMPORT ONLY) Have all aspects of M.A.904 been addressed? YES/NO

As it states this is for ‘Import Only’ so unless it is a balloon for import ignore. M.A.904 is the requirement for an Airworthiness Review for an aircraft imported into the EU from outside the EU (like Fiji for example) if you see what I mean.

3. PHYSICAL SURVEY OF AIRCRAFT

This has nothing to do with the Annual/100hour inspection it is the statement that you have prodded and poked about the balloon, basket, burner and cylinders, recorded the numbers and any engravings stating maintenance requirements like PRV replacement, AD requirements (SB 10 on Sky burners for example), checked that there is an ID plate in the basket or on the envelope and the crown ring details are correct. As balloons can have the Annual Inspection and Review carried out at the same time the Inspection Sheet can serve a dual purpose for recording the information and a copy should be attached to the Airworthiness Review Report.

3.1 Survey Report Reference No

Again reasonably straightforward and it will probably be the same as the Contract/Workpack number (ABCDddmmyyyy) at the top and have the same format and be the same number on the top of the Inspection/Survey Report Sheet which must be attached to the completed Review.

3.2 Date and Location of the survey undertaken

The place can just be the name of the town or village nearest to the field you inspected the balloon in along with the date of the inspection.

3.3 is Not Applicable. Yet!!

3.4 All known defects and problems found during the survey have been appropriately addressed YES/NO

Has to be a YES otherwise the ARC cannot be issued. Obvious really. If they haven’t been addressed then you’ll have to make sure they are jolly pronto.

3.5 List any deferred defects

Any deferred defects go here but it is the responsibility of the CAMO to ensure they are rectified as soon as possible. Deferred defects is generally permitted damage (like small damage to lower panels) and can be found in the appropriate Maintenance Manual. In the case of Ride Balloons they may be actually be entered onto the Tech Log but don’t hold your breath. If they aren’t then they need to be added.

4. RECOMMENDATION

Only an ARC Signatory can complete this and only when signed can the ARC be issued, however you can also use this to just make the recommendation for the Issue of an ARC 15a, for the Import of a balloon from outside of the EU or the transition of older balloons. In those cases the ARC will not be issued by the CAMO but the CAA.

The review period should match the dates in Part 1.

The date the Review was carried out may differ from the Physical Survey date but by no more than 30 days. We tend to do the Inspection, make everything work as it should, take the logbook and paperwork home and save it for a rainy evening so the date of the Physical is usually a few days earlier than the Review date.

Ensure the registration and serial number match the ones in Part 1.

Delete ‘was/was not’ and ‘it is/is not’ accordingly.

The Authorisation Number will be the one assigned by the CAMO you are carrying out the Review for, normally your BBAC Inspector number.

Finally, if you’ve any strength or mental ability left, sign and date the wretched thing and have a large noggin for a job well done. Of course don’t forget this is a Review and during the course of the Review you may find things that prevent the ARC from being issued. Until the Review can be completed satisfactorily the ARC or the recommendation for the issue of an ARC cannot be made. The art therefore is to ensure that everything is correct before you start the Review!

SUMMARY OF SOURCES

CAA G-INFO – definitive information on all the UK registered aircraft. http://www.caa.co.uk/application.aspx?catid=60&pagetype=65&appid=1

BBAC Pilots Circular – published on line www.bbac.org or by post via BBAC Membership Secretary. BBAC Technical Office CTO Graham Hallett cto@bbac.co.uk. Access to the site requires membership.

EASA Bi-weeklies – Summary of EASA ADs http://ad.easa.europa.eu/biweekly

EASA Website – Confused.com could help here http://www.easa.eu

EASA AD list http://ad.easa.europa.eu/

CAA Website – dreadful complicated site www.caa.co.uk

CAA CAP 747 covers all airworthiness issues. Lists TCDS including Sky & Head in 1.4. http://www.caa.co.uk/application.aspx?catid=33&pagetype=90&appid=11&mode=detail&id=1331

CAA CAP 476 covers the older stuff (pre-Sept 2004) can take a bit of time to load (its old!). http://www.caa.co.uk/application.aspx?catid=33&pagetype=65&appid=11&mode=detail&id=216

EASA TCDS list http://easa.europa.eu/certification/type-certificates/balloons.php

http://www.easa.eu.int/home/g_links.html supplies links to all the EU aviation authorities (State of Design).

Cameron Balloons www.cameronballoons.co.uk

Head Balloons www.headballoons.com or info@headballoons.com

Kubicek Balloons www.kubicekballoons.cz

Lindstrand Balloons www.lindstrand.co.uk

Ultramagic www.ultramagic.com

Schroeder http://www.schroeder-fireballoons.de/ol/index.php