I was very kindly invited to give a talk at the Icicle Dinner this year. Having ‘ummed and ‘arred about exactly what I was going to ramble on about I decided to recount a few of the really daft things I’d done and got away with. Some events were amusing, some rather more serious but all involved bonkers to one degree or another. I liked to think that it was all mainly a huge learning curve and it made us all wiser. So, in the spirit of coming out (steady) with admissions of foolhardiness I thought I’d share a few at a more serious safety-type level. Little did I realise that another would occur within a couple of months or that basic training probably saved the day. So, for a kick-off, I’m going to tell you a story about familiarity and contempt, practise and learning. As I put quill to papyrus its barely a week since the tragedy in Egypt and we went and nearly blew ourselves up a few days after which, apart from giving us a scare, left us with at least a couple of really top seriously soul searching questions, especially later, once we’d adjourned to the Swan to discuss exactly what had happened and how to stop it happening again. Then we realised that we’d nearly (but hadn’t) missed something equally as potentially serious but were saved by procedure.

I was very kindly invited to give a talk at the Icicle Dinner this year. Having ‘ummed and ‘arred about exactly what I was going to ramble on about I decided to recount a few of the really daft things I’d done and got away with. Some events were amusing, some rather more serious but all involved bonkers to one degree or another. I liked to think that it was all mainly a huge learning curve and it made us all wiser. So, in the spirit of coming out (steady) with admissions of foolhardiness I thought I’d share a few at a more serious safety-type level. Little did I realise that another would occur within a couple of months or that basic training probably saved the day. So, for a kick-off, I’m going to tell you a story about familiarity and contempt, practise and learning. As I put quill to papyrus its barely a week since the tragedy in Egypt and we went and nearly blew ourselves up a few days after which, apart from giving us a scare, left us with at least a couple of really top seriously soul searching questions, especially later, once we’d adjourned to the Swan to discuss exactly what had happened and how to stop it happening again. Then we realised that we’d nearly (but hadn’t) missed something equally as potentially serious but were saved by procedure.

The week previous we’d inspected a Cameron Quad burner, a pair of Stealth burners and a pair of Mk 4 Supers, as part of the annual on a large ride balloon. Now, after all the touchy feely and sniffing and looking, as a matter of course, we always run neat propane through the system before lighting anything and, after checking for escaping propane where it shouldn’t be, light it up. Pretty much what you do on a burner test but we are expecting leaks and looking for them! So, all lived-up, we opened the whisper valve on one of the pair of Stealths. The air filled with a mighty cloud of liquid propane. The valve was rapidly closed but propane continued to flow. Shut the cylinder valve and it died away. Try again and try to spot where the leak was. It appeared to be the valve itself not shutting properly. Problem noted as leaking whisper valve move on to the next. We’d check the main valve after the liquid valve was cured. Not a real problem for the client as this can usually be adjusted, if not then replace the whisper valve stem. We’d try and adjust it after the inspection was completed lest there were any other nasties that needed doing but the anxious owner interrupted. Could it be fixed there and then as it transpired the balloon was due to fly in the morning? “Well its probably just adjustment, we’ll give it a go”. We did and it didn’t cure it. Owner now bereft. Simple solution was to swap burners for a pair off a triple that were OK, change the details in the logbook and all was well. That was what we did and loaded the faulty set in the car to repair and carried on with the inspection. All was fine and dandy.

Fast forward to a few days later back in the workshop. The faulty burner, along with the inspection sheet, now sits rather forlornly on the bench. An attempt is made to adjust the valve again but to no avail. An air test shows it is still leaking through the jet when shut off. We strip it down to discover that the seat on the valve stem is well-poorly so replace it. As is normal practise we then run air at 100psi through the lot and it all seems fine. Open the air rushes out, closed not a murmur. Repeat with leak detector and all is fine. Job done. Its getting late and the owner is due in a couple of hours but it seems all is sorted. Brilliant. All we need to do is a live test and this is where things nearly go very badly wrong.

It is cold and raining. The workshop heater is a rocket propane burner running off the mains powered by a standard Propane cylinder running at around 12psi, just inside and pointing down the shed. We open the roller shutter and stand the burner just inside so as it doesn’t get wet and aim it at the Thunderbox opposite. Livening it up for the liquid test the most extraordinary, unexpected, huge cloud of propane escapes from the bottom of the can and proceeds to head inside the workshop drawn by the air grabbing heater. John, supporting the frame, rather forcefully suggests it would be a good idea to turn the heater off, which we do, shutting down the cylinder connected to the burner and the one to the heater at the same time. The workshop consumes the last of the leaking propane as the hose empties. No one dares move until it all dissipates. Somehow nothing catches fire and we head for the Scotch, shaken but not stirred!

It is cold and raining. The workshop heater is a rocket propane burner running off the mains powered by a standard Propane cylinder running at around 12psi, just inside and pointing down the shed. We open the roller shutter and stand the burner just inside so as it doesn’t get wet and aim it at the Thunderbox opposite. Livening it up for the liquid test the most extraordinary, unexpected, huge cloud of propane escapes from the bottom of the can and proceeds to head inside the workshop drawn by the air grabbing heater. John, supporting the frame, rather forcefully suggests it would be a good idea to turn the heater off, which we do, shutting down the cylinder connected to the burner and the one to the heater at the same time. The workshop consumes the last of the leaking propane as the hose empties. No one dares move until it all dissipates. Somehow nothing catches fire and we head for the Scotch, shaken but not stirred!

What happened there then? Rather tentatively we have another go at livening up the system ensuring everything electrical on the planet is off and the fire extinguisher is even closer by. Checking the whisper valve is fully closed we crack the cylinder valve open a tad and close it immediately. The leak now appears to be coming from the base of the block even when turned off at the cylinder. There is nothing else to do but strip it down again. We take the block out, fit some blanks to the gauge and crossover and apply air. Its seems to be leaking from the gauge connector on the block.

What happened there then? Rather tentatively we have another go at livening up the system ensuring everything electrical on the planet is off and the fire extinguisher is even closer by. Checking the whisper valve is fully closed we crack the cylinder valve open a tad and close it immediately. The leak now appears to be coming from the base of the block even when turned off at the cylinder. There is nothing else to do but strip it down again. We take the block out, fit some blanks to the gauge and crossover and apply air. Its seems to be leaking from the gauge connector on the block.  We take it out, clean it up, check for cracks and refit it. Try again. Now its coming from under the whisper valve lower body. We screw the whisper valve assembly out and proceed to undo the lower body of the whisper valve assembly to have a gander and bink… it comes completely adrift leaving the threaded portion in the block. That was it then, there was a fracture in the lower body. Sure the valve wouldn’t close because the seat was kernadgered but there was a secondary fault that never showed up until we’d changed the stem. On top of this the adaptor for the gauge was also leaking.

We take it out, clean it up, check for cracks and refit it. Try again. Now its coming from under the whisper valve lower body. We screw the whisper valve assembly out and proceed to undo the lower body of the whisper valve assembly to have a gander and bink… it comes completely adrift leaving the threaded portion in the block. That was it then, there was a fracture in the lower body. Sure the valve wouldn’t close because the seat was kernadgered but there was a secondary fault that never showed up until we’d changed the stem. On top of this the adaptor for the gauge was also leaking.

So what is the lesson here? If we hadn’t turned the heater off in time we would have had a seriously major fire. After a long time discussing the ‘what-if-maybes’ we all agreed we had been completely daft and we’d ignored all our normal practises. Why on earth leave an ignition source running that dragged air in then go and do a live test? Muppetry of the nenth scale. It was a sobering thought that despite being well aware of the risk we had been very close to disaster! Normally we always shut the heater down whenever we do anything vaguely propane. Now, on the other hand, what prevented the disaster. Well that would be knowing how to turn the heater and its supply off along with shutting the supply to burner as soon as the problem occurred which only left a hose length of propane to escape through the fracture. We were undeniably lucky but, in our defence, faced with the situation, we did all react correctly, without panic, to the situation. That came naturally. That we allowed the situation to arise was not so clever. On the technical side there were clearly three faults and repairing one brought the others to the fore. We’d fallen into the assumption/distraction trap. Bad form. Quite why the component had fractured is open to question. The stupid thing was we’d seen it once before a few years ago when one had possibly been overtightened at some stage in its life. The way it is sealed into the block is contrary to normal practise in that the threads are parallel and the seal is formed by a few wraps of PTFE tape and Loctite. It would be normal to use a gasket or sealing ring for such a connection. Overtightening is the most likely cause and after years of cycling the tiny fracture grew until failure was mandatory. The offending item is off to Camerons for a poke and a prod.

So what is the lesson here? If we hadn’t turned the heater off in time we would have had a seriously major fire. After a long time discussing the ‘what-if-maybes’ we all agreed we had been completely daft and we’d ignored all our normal practises. Why on earth leave an ignition source running that dragged air in then go and do a live test? Muppetry of the nenth scale. It was a sobering thought that despite being well aware of the risk we had been very close to disaster! Normally we always shut the heater down whenever we do anything vaguely propane. Now, on the other hand, what prevented the disaster. Well that would be knowing how to turn the heater and its supply off along with shutting the supply to burner as soon as the problem occurred which only left a hose length of propane to escape through the fracture. We were undeniably lucky but, in our defence, faced with the situation, we did all react correctly, without panic, to the situation. That came naturally. That we allowed the situation to arise was not so clever. On the technical side there were clearly three faults and repairing one brought the others to the fore. We’d fallen into the assumption/distraction trap. Bad form. Quite why the component had fractured is open to question. The stupid thing was we’d seen it once before a few years ago when one had possibly been overtightened at some stage in its life. The way it is sealed into the block is contrary to normal practise in that the threads are parallel and the seal is formed by a few wraps of PTFE tape and Loctite. It would be normal to use a gasket or sealing ring for such a connection. Overtightening is the most likely cause and after years of cycling the tiny fracture grew until failure was mandatory. The offending item is off to Camerons for a poke and a prod.

Some years ago I failed a chap on his PPL checkflight. It wasn’t one thing but, as is always the case, a combination of events that led to his downfall. He was without doubt the kindest, nicest person you could ever meet. His final undoing was a Colt C2 Plus. This is a single burner but with duplicated valves and pilot lights. At some point during the flight a cylinder was changed and the correct blast valve to operate the new cylinder couldn’t be identified. The outcome was one pilot light got turned off. This caused so much confusion that the other pilot light, related to the, still live, other blast valve was turned off. This wasn’t good and a rush groundwards ensued. Some rather hurried retorts got at least one side working and a serious limp was averted. We made an appointment to run through some familiarity lessons up the yard a few days later with the assembled bottom end, this time safely on the ground. By the end of the afternoon he could operate pilot light valves, blast valves and whisper valves with his eyes shut and change cylinders standing on his head. He passed his check flight a few months later with flying colours.

Where, you may ask, with Greg Lake going on about ‘elephants scream with napalm fire’ reverberating through your Dynatron headphones, is all this leading. Simple really. Procedure and practise. When I learnt to glide, and later fly something with an engine bolted on the front, safety procedures were rammed down your throat from the words ‘All out’. First lesson gliding was what to do when the launch cable broke. Thereafter every launch involved a question, a simulated cable break or an actual cable break until you didn’t need to think about it. When it happened on my second solo it was more irritating than frantic. With fixed wing I clearly remember, very early on, the instructor asking me where I could land should the engine stop. Next time he asked if I could get into the field I’d chosen should the engine stop. Couple of sorties later he shut the engine down and explained about carb icing and how it would be a good idea to turn the carb heat on if I was going to leave the engine idling whilst I valiantly performed an ‘S’ shaped approach to a huge wheat field. After that we went on to ‘how to try and restart the thing’ and ‘how long before you gave up and started heading for Yasgur’s Farm again’. With balloons the first landing cry was “Pilot Lights Off NOW!”

Ballooning is no different but a whole lot less complicated and certainly a lot more forgiving, unless you miss the point. Training includes emergency procedures but how often do we practise them once we become Skygods? When did you last have a fire on the ground, pilot light failure, imminent contact with ground because of curl-over, a panicking passenger or one having cardiac arrest? When did you last forget the box of matches or your map? Can you actually read a ½ mill Airmap? What did you do? How did you react? When did you last practise an emergency landing and choose a field to get into at short notice? Truth is that we generally bumble along and choose somewhere suitable to land without a second thought, the biggest worry being that the retrieve keys are in your pocket. Now, I’m not saying we are not aware of what’s going on during the flight from the moment we float away or that we are not constantly aware of where we could land in an emergency but do you practise emergency procedures? With enough hours you are probably doing it automatically, without a second thought, but what if it all goes wrong at the last moment? Could you cope? How quickly could you get the fire extinguisher out of its plushly padded cell, or lay your hands on the Swan Vestas? Would you remember to tell the passengers to hang on for dear life in the correct manner? What’s your call sign to the retrieve if you have a problem? How would your crew react to an emergency? What is the emergency frequency?

Flying is four dimensional. You never stop learning. Last year I did a check flight for a young (relatively you understand) fellow who carried out a most unusual pre-flight burner test. He did everything correctly and in the correct order eventually lighting the pilot with the piezo and finishing his burner test. He then turned on the otherside, checked and sniffed, and lit the pilot with a striker. The burner test was then repeated using the igniter. Fine I thought and asked if the igniter was faulty. “No”, he answered, confidently putting me firmly in my place, “I have always had a problem knowing exactly where to light the pilot with a striker so I do it everytime. I can now do it with me eyes shut.” Brilliant, who’d have thought. I now incorporate that in my training regime.

The airline industry spends hours locking their pilots into simulators practising coping with the unexpected. My late uncle once told me that having been in a VC10 simulator for four hours and now well over the Atlantic with one undercarriage door open, half the electrics shot to bits, an intermittent fault with the auto-pilot and a large electrical storm brewing on the horizon one of the simulator engineers popped his head through the side window and asked if his sandwich box was anywhere about. The pilot’s and flight engineer’s reactions were very automatic.

The airline industry spends hours locking their pilots into simulators practising coping with the unexpected. My late uncle once told me that having been in a VC10 simulator for four hours and now well over the Atlantic with one undercarriage door open, half the electrics shot to bits, an intermittent fault with the auto-pilot and a large electrical storm brewing on the horizon one of the simulator engineers popped his head through the side window and asked if his sandwich box was anywhere about. The pilot’s and flight engineer’s reactions were very automatic.

So what could we have missed that was equally chilling? Well it appears that during the episode of getting Mr Ride Operator back in the air on site we had been distracted from our own inspection regime and, lo and behold, during the rebuild and test back in the workshop it was noted that the liquid hose on the other burner was worn down to the metal re-enforcing where the candy line had been running over it. If we had spotted it during the inspection it hadn’t been noted. Now maybe it was and, in the ensuing appearance of vast amounts of liquid propane and the need to get the thing in the air the following morning by switching burners, it was forgotten, or maybe it was noted but not recorded. On the second very successful test, which included both burners, just ahead of the clients’ arrival we spotted the damaged hose. Fortunately we had one in stock so it was fitted and yet another test carried out. We found it because our procedure meant that the complete system was rechecked but had it been on the other pair there was a possibility that during the distractions changing the burners it may have got missed. I like to think not. There were certainly a few items that needed serious discussion and that is exactly what you have to do whenever anything goes awry in aviation otherwise you may not get a second chance. Discuss we did. Slapping yourself with a four by two every few years is seemingly very necessary. It won’t happen again.

What did we learn or, rather, what did we do right and what didn’t we do that we always did that nearly invoked The Return of the Fire Witch?

Number One, ensure there are no sources of ignition prior to testing anything involving live propane. Simple enough, that is the rule for the pre-flight burner test, ‘lead with liquid light last’. Quite properly we didn’t have the pilot running when we turned on the propane.

Number two, don’t be distracted by events unfolding. Follow your own procedures. We broke the inspection to attempt to repair a seemingly simple fault that ended up involving swapping burners. We should have continued the inspection then taken stock of the repairs necessary. Daft? That is what we thought we always did!

Number three, be aware that things will always go wrong when you least expect them to and more often than not it’s a combination of events or failures that is to blame. Just because you think you’ve sorted the source of the problem be prepared for the unexpected. Mistakes mainly occur doing routine things like changing cylinders or maps.

Number four Practise emergency procedures as a matter of course. You don’t have to frighten your passengers witless but at least run through them in your mind. If you don’t have to think about the reacting bit you will gain yourself extra time to sort the problem.

Now, remember this all happened when we were not in the air. The fitting could have failed in flight but it is more likely it would have been spotted during the next pre-flight burner check. Had it not then a fire would have ensued as the pilot light would have been on. Shutting down the cylinder would have solved the problem but in this case a 3.5 metre hose contains a lot of propane and it could have been spiked with nitrogen. If you think about, and practise, emergency procedures they will become second nature. There are three dangerous things about balloons. The fan, the propane and the pilot. Switch on to danger when the balloon basket comes out the trailer and don’t switch off during the landing approach, the actual landing, or until you come to a grinding halt and everything is turned off and then check again that it is turned off.

Now, remember this all happened when we were not in the air. The fitting could have failed in flight but it is more likely it would have been spotted during the next pre-flight burner check. Had it not then a fire would have ensued as the pilot light would have been on. Shutting down the cylinder would have solved the problem but in this case a 3.5 metre hose contains a lot of propane and it could have been spiked with nitrogen. If you think about, and practise, emergency procedures they will become second nature. There are three dangerous things about balloons. The fan, the propane and the pilot. Switch on to danger when the balloon basket comes out the trailer and don’t switch off during the landing approach, the actual landing, or until you come to a grinding halt and everything is turned off and then check again that it is turned off.

I was very fortunate to have come into ballooning after learning other flying disciplines and as it was my old man who taught me to fly gliders, along with a chap appropriately named Dicky Bird. Mistakes were not permitted. Very old school. When I realised you could earn a living flying balloons I was almost immediately ‘on the circuit’ which meant that as soon as you were airborne you were looking for somewhere to land (often that translated into ‘needed to land’) and as the kit wasn’t always in the best of health emergencies were not so much commonplace but expected! All these rules apply on the ground and in the air and all that practise may well save you one day, but don’t forget the most important people in ballooning are the crew and they also need training. They need to have the same disciplines. Some day they may save you from yourself.

I was very fortunate to have come into ballooning after learning other flying disciplines and as it was my old man who taught me to fly gliders, along with a chap appropriately named Dicky Bird. Mistakes were not permitted. Very old school. When I realised you could earn a living flying balloons I was almost immediately ‘on the circuit’ which meant that as soon as you were airborne you were looking for somewhere to land (often that translated into ‘needed to land’) and as the kit wasn’t always in the best of health emergencies were not so much commonplace but expected! All these rules apply on the ground and in the air and all that practise may well save you one day, but don’t forget the most important people in ballooning are the crew and they also need training. They need to have the same disciplines. Some day they may save you from yourself.

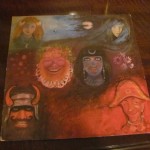

So, as the more astute of you, whilst reading this, are trying to remember if 21st Schizoid Man is on In the Wake of Poseidon or Court of the Crimson King and that you reckoned Greg Lake was in Emerson, Lake and Palmer and did they play Woodstock and then you have to re-read a bit because your mind has wandered demonstrating, very nicely, distraction of the worst type, uncertainty. I rest my case.

is on In the Wake of Poseidon or Court of the Crimson King and that you reckoned Greg Lake was in Emerson, Lake and Palmer and did they play Woodstock and then you have to re-read a bit because your mind has wandered demonstrating, very nicely, distraction of the worst type, uncertainty. I rest my case.